We’ve finally done it! Our engineering team LumaLab has perfected the formula for UV-curing glue. Our engineers have developed a specialized UV-curing compound designed to provide robust and long-lasting bonds for our oculars. But the UV-curing glue is just one piece of the puzzle. LumaLab also conducts numerous meticulous tests to ensure we deliver the highest quality products to our customers.

LumaLab Engineers Ryan and Kevin

The UV Curing Process: Immediate and Efficient

The UV-curing process is an integral part of our production here at LumaDent. Right after the loupes are assembled, they go straight to UV-curing. This ensures that the glue sets quickly and uniformly, creating a strong, reliable bond every time. This efficient method not only speeds up production but also makes the bonding process repeatable and predictable. This means you can trust that every pair of loupes we produce meets the high standards we set for durability and performance. By streamlining this step, we ensure that our products are always top-notch and uniform, giving you the best tools for your practice.

Handling UV-Curing Glue

Proper storage is equally essential to prevent unintended curing, especially under fluorescent lights. The glue is stored in black containers to prevent ambient UV light from curing it. Each shipment of UV-curing glue also has an approximate shelf life of up to six months when stored and maintained in the proper conditions.

While UV-curing glue offers exceptional benefits and strong durability, handling it with care is important. UV-curing glue is highly effective but also comes with significant dangers. It is extremely toxic and should never be ingested or come into contact with skin. Proper safety measures such as adequate ventilation and protective equipment are essential when handling this adhesive to prevent health risks while it is in its liquid state. However, once the glue has been cured, it is 100% safe to handle.

Rigorous Testing Methods for Bond Durability

To ensure the durability of our loupes, the LumaLab team conducts several rigorous tests using a universal testing machine. These tests include:

- Bend Test: Assesses the flexibility and resistance of the glue under bending forces. The universal testing machine applies controlled bending to the loupes, measuring the adhesive’s capacity to maintain its bond without cracking or failing. The intrinsic strength characteristics we test here are the Shore levels of the bond.

- Color Test: Examines whether the glue maintains its color integrity during use, after production, and following UV curing. This ensures that the adhesive does not discolor, which could indicate degradation or reduced effectiveness.

- Shear Test: Measures the adhesive strength when shear forces are applied. Using the universal testing machine, this test ensures that the glue can withstand lateral forces without compromising the bond between components.

- Life-Time Testing: This test was designed to simulate the durability of our loupes' temple arms by counting how many times they can be opened and closed before showing signs of wear and tear. The machine can perform any number of programmed cycles each day on a pair of loupes.

- Heat Test: The test evaluates the glue's performance under high-temperature conditions. By exposing the loupes to elevated temperatures, the universal testing machine assesses the longevity and stability of the adhesive bond in various thermal environments.

Future Testing Methods

As part of our commitment to excellence and adherence to the latest regulations, we are gearing up for a series of new tests to comply with the European Union's Medical Device Regulation (MDR). The MDR emphasizes the need for rigorous testing to ensure the highest standards of safety and performance for medical devices. One of the critical areas we will be focusing on is environmental testing. These tests are designed to assess how our products perform under various environmental conditions, such as temperature fluctuations, humidity, and exposure to different chemicals. By understanding how these factors impact our products, we can further enhance their durability and reliability, ensuring they perform optimally in any setting.

To meet the stringent requirements of the new EU MDR regulations, we send our products to ISO-certified laboratories for third-party testing. These labs are equipped with state-of-the-art technology and staffed by experts who conduct a comprehensive range of tests to verify that our products meet all necessary standards. This includes everything from mechanical and chemical tests to more specialized evaluations like biocompatibility and sterility. By partnering with ISO-certified labs, we can guarantee that our products not only comply with regulatory requirements but also deliver the highest quality and performance to our customers. This approach to compliance and quality control is a cornerstone of our mission at LumaDent, as we strive to provide innovative, high-quality, and reliable products for dental professionals worldwide.

Universal Testing Machine

Ensuring Bond Strength and Durability

A Universal Testing Machine (UTM) is a versatile device used to test the mechanical properties of materials and components. It performs various tests such as tensile, compressive, and flexural tests, making it essential in industries like manufacturing, construction, aerospace, and biomedical engineering. The UTM helps determine a material's strength, flexibility, and durability under different conditions, ensuring product reliability and performance.

There are two types of UTMs: single-column and dual-column. We use a single-column UTM because it provides all the force we need for our tests. The primary difference is that dual-column UTMs can provide more force, which is necessary for testing materials that require higher loads.

Key components of a UTM include a load frame, crosshead, grips and fixtures, load cell, and a control system. These components work together to apply and measure forces on the test specimen, providing precise data for quality control, research and development, and failure analysis. When the UTM measures the test being conducted, the data is shown and updated in real-time on a computer screen in the form of graphs. By using a UTM, companies can ensure their products meet industry standards and specifications, enhancing overall product excellence.

Applications:

- Failure Analysis

- Quality Control

- Material Testing

- Research and Development

The universal testing machine is crucial in our quality assurance process. It tests the bond strength of the adhesive between the oculars and the lens, ensuring they meet our high standards before reaching customers.

Quality Control: Inspection Protocols and Steps

Each batch of UV-curing glue is thoroughly inspected. We have a quality control checklist that our technicians go over to inspect each product. Our protocols include post-curing inspections where technicians look for potential issues such as:

- Weak Points in the Adhesive Bond: Technicians perform a visual inspection for weak points in the adhesive bond. This step ensures that the glue has cured correctly and will maintain its strength under normal usage conditions.

- Smudges or Surface Imperfections: The inspection process also looks for smudges or surface imperfections. These could indicate improper application or curing, which might compromise the glue's effectiveness.

- Color Changes in the Glue: One of the critical inspections involves checking for color changes in the glue. This helps in identifying any degradation or chemical instability that could affect the product's performance.

- Breakage Characteristics (micro-cracks): The inspection includes analyzing breakage characteristics, such as micro-cracks. This helps in understanding the adhesive's behavior under stress and ensuring it meets durability standards.

- Who Does the Checks: Our talented team of technicians who complete the QC Checklist are some of the most important people at LumaDent. They verify that the product was made correctly, they clean the dust and debris built up during production, and they test the convergence and alignment of the loupes.

Weight Durability Testing

Our weight durability tests have shown just how strong our loupes are. Each ocular can handle up to 100 lbs before breaking, thanks to our new and improved UV-curing glue and solid design. Our loupes are designed to endure long surgeries and regular wear and tear, providing reliable performance day after day, week after week. However, it's still important to treat them with care to maintain product integrity. It’s best to avoid putting heavy objects on your loupes or exposing them to extreme conditions. Following these simple tips will help ensure your loupes stay in great shape for years to come.

Extending the Lifespan of Your Loupes

To maximize the lifespan of your loupes, it is important to follow proper care guidelines:

- Avoid using Alcohol-Based Cleaners: It is imperative to NEVER use any alcohol-based cleaning products when sanitizing your loupes. The acid in alcohol deteriorates the glue's structural integrity holding the oculars in place.

- Maintain a Temperature-Controlled Environment: Do NOT store your loupes in extreme temperatures, such as inside a car, where temperatures can exceed 160 degrees Fahrenheit. High temperatures break down and deteriorate the glue’s bond holding the oculars together. The best place to store your loupes is at your office where the temperature is more easily regulated.

- Handle with Care: While we use the strongest material available and test religiously, it is still important to handle your product with care. These products are bespoke and are tailor-made for you. Each of these loupes are measured within a few millimeters of accuracy to your physical measurements. Therefore a slight shift of even 1 millimeter may throw off the alignment of the loupes.

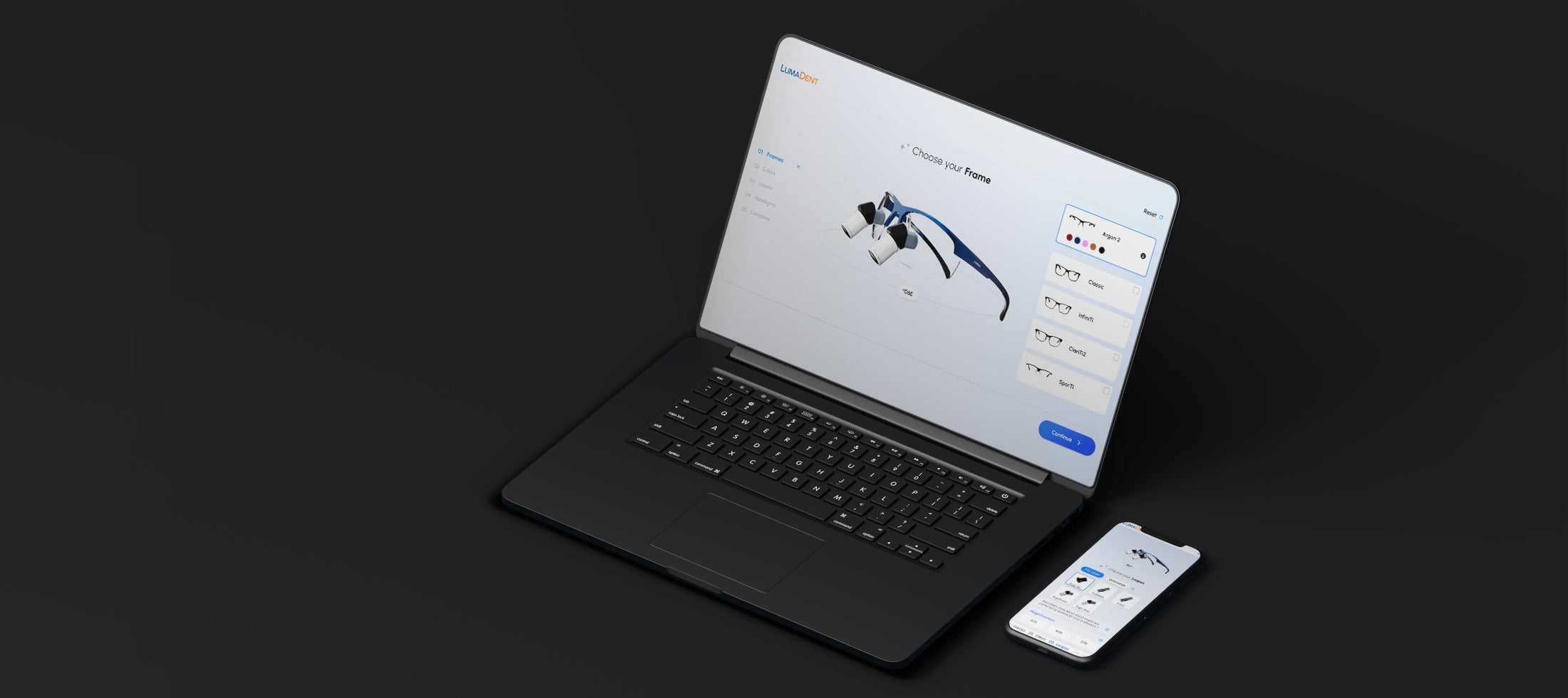

Visit Our Designer Studio

We invite you to visit our Designer Studio to customize your loupes and experience the benefits of our advanced glue technology. Our commitment to quality and innovation ensures that you receive the best products to support your practice.

By following these guidelines and understanding the rigorous testing and quality control processes at LumaDent, you can be confident in the durability and performance of your loupes. Thank you for choosing LumaDent!

Visit our Designer Studio to customize your loupes and take advantage of our Special Deals!

Share:

Dr. Don Ton & Dr. Glenn Vo Podcast

The HL360 vs. the 360 Pro: What's the Difference?